Tristan Ishtar

VP of Sales

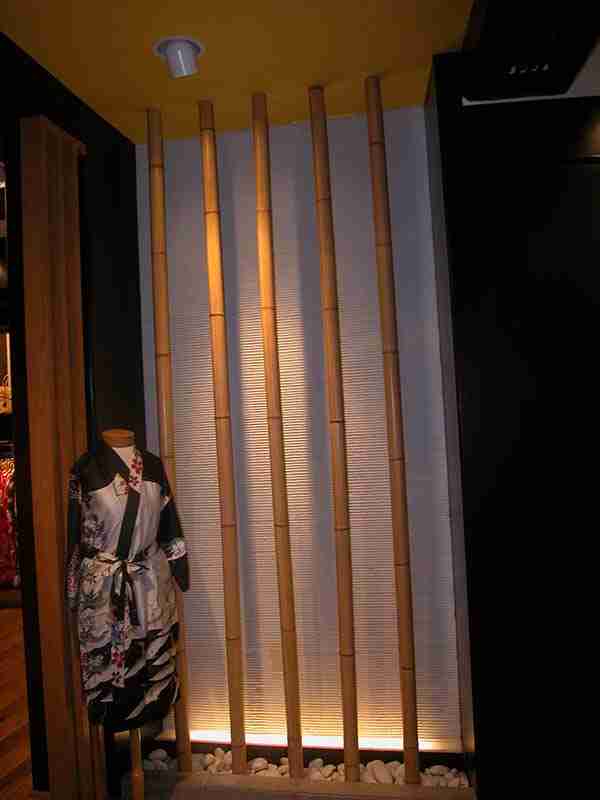

Selecting the right bamboo poles can mean the difference between a stunning installation that lasts decades and a disappointing project that requires premature replacement. With numerous bamboo species, treatments, and synthetic alternatives available, making informed choices requires understanding how different options perform across various applications.

This comprehensive bamboo pole selection guide helps you navigate the decision-making process, whether you’re designing a commercial resort or creating a backyard tiki bar.

Step 1: Determine Your Project Requirements

Before evaluating specific bamboo options, clearly define your project parameters. The answers to a few key questions will narrow your choices significantly and prevent costly mismatches between materials and applications.

First, consider your installation environment. Will bamboo poles be used indoors or outdoors? Indoor applications offer protection from weather, UV exposure, and moisture, allowing you to use less durable species that would fail in exterior settings. Outdoor installations face rain, sun, temperature fluctuations, and potential pest exposure—all factors demanding more robust materials.

Climate plays an equally important role. Dry desert regions like Arizona preserve natural bamboo far longer than humid coastal areas where moisture accelerates decay. If your project sits in a wet climate with regular rainfall, factor in either synthetic alternatives or aggressive treatment protocols for natural bamboo. Coastal installations must account for salt air’s corrosive effects on both bamboo and hardware.

Your bamboo’s structural role determines species requirements completely. Decorative ceiling treatments require minimal strength since poles bear no loads and face no physical stress. Support columns, pergola beams, and fencing must withstand wind loads, physical impacts, and sometimes human weight. Using non-structural bamboo species for load-bearing applications creates dangerous failures regardless of how attractive the poles appear initially.

Budget considerations extend beyond initial purchase price to include installation costs, maintenance requirements, and replacement cycles. Natural bamboo costs less upfront but may require periodic sealing and eventual replacement. Synthetic bamboo commands premium pricing but eliminates maintenance and lasts far longer. Calculate total cost of ownership over your expected project lifespan rather than focusing solely on initial material costs.

Step 2: Compare Natural Bamboo Species

Natural bamboo poles fall into distinct categories based on strength, appearance, and appropriate applications. Understanding these differences ensures you select species matched to your needs.

Structural Bamboo Species

Structural bamboo varieties possess the thick walls and dense construction necessary for load-bearing applications. These species can function similarly to dimensional lumber when properly treated and installed.

Solid bamboo poles feature walls comprising 60-99% of their diameter, leaving minimal hollow center. This dense construction provides exceptional strength for support columns, pergola framing, and robust fencing. The thick walls resist splitting when drilled for hardware installation and maintain structural integrity under stress.

Tre-Gai bamboo grows with pronounced rustic nodes and thick walls that create dramatic visual texture. These large-diameter poles excel in applications where bamboo becomes a focal point rather than just functional material—think resort lobby columns or tiki bar frameworks where the pronounced nodes photograph beautifully and provide authentic tropical character.

Guadua bamboo, native to South America, ranks among the strongest bamboo species available. Construction industries in bamboo-growing regions use Guadua for scaffolding and structural frameworks, testament to its impressive load-bearing capacity. For projects requiring maximum strength, Guadua delivers performance that rivals many traditional building materials.

Non-Structural Decorative Bamboo

Tonkin bamboo dominates the decorative bamboo market due to its uniform appearance and economical pricing. The smooth surface and consistent diameter create clean lines ideal for ceiling treatments and wall coverings. However, Tonkin’s thin walls and lower density make it completely unsuitable for structural applications or outdoor use without protection.

Indoor decorative installations represent Tonkin’s sweet spot. Restaurant ceilings, bar backdrops, and protected wall treatments benefit from Tonkin’s affordability and attractive appearance. Just understand the limitations—this species will crack and split if used outdoors or in applications involving physical stress.

Step 3: Consider Synthetic Bamboo Alternatives

Technological advances have produced synthetic bamboo options that address natural bamboo’s primary limitations while maintaining visual authenticity. For demanding commercial applications or challenging environments, synthetic alternatives often prove superior despite higher initial costs.

Artificial Interlocking Bamboo

This innovative system features modular sections made from nylon polyamide that connect to create custom lengths. The 18″-20″ segments interlock with virtually invisible joints, allowing you to build poles of any desired length without waste or cutting. The hollow center design accommodates electrical wiring, plumbing, or LED lighting for integrated installations.

Fire-retardant properties make artificial interlocking bamboo essential for commercial projects where building codes restrict natural materials. Theme parks, restaurants, and resorts benefit from the 10-year warranty and zero maintenance requirements. UV-resistant formulation prevents fading in high-sun environments, maintaining appearance without periodic refinishing.

The modular nature also simplifies shipping and storage. Rather than coordinating freight for lengthy natural poles, compact boxes containing interlocking sections ship via standard carriers and store efficiently until installation.

HDPE Synthetic Poles

High-density polyethylene poles offer another synthetic option particularly suited to water features and high-moisture environments. These poles withstand constant water exposure, chlorinated pool areas, and salt air that would destroy natural bamboo within months.

Available in custom colors including natural tan, green, or project-specific hues, HDPE poles integrate seamlessly into themed environments. The hollow construction hides utilities while the unlimited indoor warranty and 10-year outdoor coverage provide long-term budget predictability.

For water park applications or resort pool areas, HDPE synthetic bamboo delivers performance natural alternatives simply cannot match.

Step 4: Determine How You Will Treat Your Bamboo Poles

Treatment dramatically affects natural bamboo’s lifespan and performance.

Standard Boron Treatment

Quality structural bamboo receives tank treatment with boron compounds that prevent Powder Post Beetle infestation. These insects bore through untreated bamboo, creating galleries that weaken poles and compromise structural integrity. Boron treatment creates a hostile environment for beetles while remaining safe for humans and animals.

Properly treated bamboo lasts 6-8 years outdoors without additional maintenance, extending to 12-15 years with periodic sealing. Untreated bamboo may fail within 2-3 years in humid climates, making treatment essential for outdoor installations.

Fire-Retardant Processing

Commercial applications often require fire-retardant bamboo meeting Class A ratings. Surface-applied fire retardants provide effective protection while maintaining reasonable production timelines. These coatings meet building codes and work well for most commercial installations, though they may require periodic reapplication in high-traffic areas.

Weather Sealants

Even treated bamboo benefits from periodic weather sealing in outdoor applications. Thompson’s Water Sealer or similar products applied every 2-3 years significantly extend lifespan by preventing moisture penetration. This maintenance adds modest cost but doubles the service life of outdoor bamboo installations.

Step 5: Choose the Correct Bamboo Pole Diameter and Length

Bamboo poles come in various diameters and lengths suited to different applications. Matching size to use optimizes both aesthetics and structural performance.

Diameter Considerations

Smaller diameters (1″-1.5″) work well for decorative fencing, garden trellises, and ceiling treatments where visual delicacy suits the design intent. These sizes cost less and weigh less, simplifying installation.

Mid-range diameters (2″-3″) serve most commercial applications including bar fronts, moderate-height fencing, and pergola cross-members. These sizes balance strength with manageable weight and reasonable costs.

Large diameters (3″-4″+) create dramatic focal points as support columns, entrance features, or major structural elements. The visual impact justifies higher costs in signature applications where bamboo becomes a defining design element.

Length Options

Standard lengths include 8′, 10′, and 12′ poles that accommodate most residential and commercial projects. These common sizes ship readily and stock consistently. Longer poles up to 19′ are available but incur premium freight charges due to dimensional shipping requirements.

Custom lengths minimize cutting waste for projects with specific dimension requirements. However, custom orders extend lead times and may carry price premiums compared to stock sizes.

Final Thoughts

Effective bamboo pole selection balances aesthetics, performance requirements, budget constraints, and maintenance considerations. Start by honestly assessing your structural needs—never compromise safety by using decorative species for load-bearing applications.

Consider your project timeline when evaluating natural versus synthetic options. Natural bamboo with standard treatment ships quickly, while fire-retardant processing or synthetic alternatives may require longer lead times. Plan accordingly to avoid project delays.

For commercial applications with long operational horizons, synthetic bamboo often proves more economical despite higher initial investment. Residential projects in protected climates may find natural bamboo delivers excellent value with proper treatment and maintenance.

Expert Guidance Makes the Difference

Bamboo pole selection involves numerous variables that interact in complex ways. Working with experienced suppliers who understand these relationships helps you avoid expensive mistakes and achieve optimal results for your specific application.

Ready to select the perfect bamboo poles for your project? Contact amaZulu at (877) 243-5309 or email [email protected] for expert guidance on species selection, treatment specifications, and sizing. Our team has helped thousands of customers choose bamboo poles for applications ranging from backyard projects to major theme park installations.

Tristan Ishtar

VP of Sales

With over 11 years at amaZulu, Tristan brings deep expertise in tropical building materials and a customer-focused approach. He serves as a trusted consultant for architects and designers, providing expert guidance without high-pressure sales.