Tristan Ishtar

VP of Sales

Selecting the correct bamboo pole diameter is one of the most important choices in commercial construction and theming. The wrong size can lead to structural weaknesses, costly replacements, and project delays—while the right size ensures strength, safety, and long-term performance.

Bamboo diameter selection goes far beyond appearance or price. It requires a clear understanding of load requirements, installation methods, and durability expectations. When chosen correctly, bamboo provides decades of reliable performance and authentic aesthetics, often at a fraction of the cost of traditional building materials.

Bamboo Diameter Classifications: An Overview

The bamboo industry uses standardized diameter ranges that directly correspond to structural capabilities and appropriate applications.

Small Diameter Poles (1-2 inches)

Small diameter poles excel in applications where visual texture and authentic bamboo aesthetics matter more than structural capacity. These poles work beautifully for interior wall coverings, ceiling treatments, and decorative screening where they’re protected from weather and physical stress.

Restaurant designers frequently use 1.5-inch poles for bar facades and room dividers, while theme park creators rely on them for detailed accent work that needs to photograph well under various lighting conditions. However, these poles cannot handle significant loads and should never be used for structural applications, even seemingly light ones like fencing in windy areas.

Medium Diameter Poles (2-3 inches)

This range represents the workhorse of commercial bamboo construction, offering the best balance between cost, availability, and performance for most projects. The 2-3 inch range handles moderate structural loads while remaining easy to work with during installation.

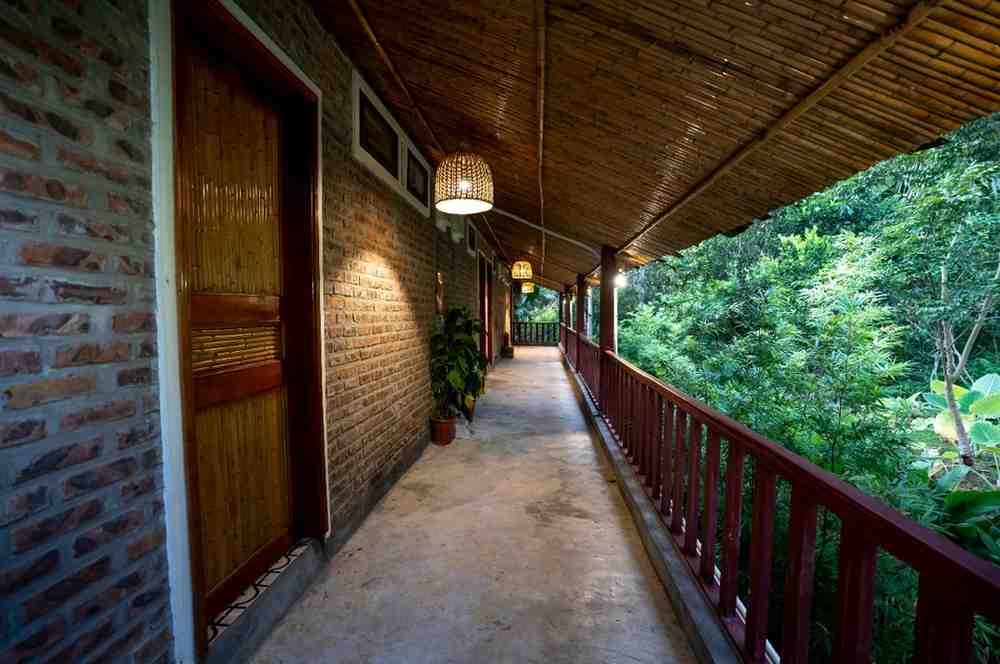

Resort designers particularly appreciate this size for pergola construction, privacy fencing, and covered walkway structures where the poles need to support their own weight plus modest additional loads like fabric canopies or light fixtures. These poles also drill cleanly without splitting, making them ideal for projects requiring multiple connections or custom hardware mounting.

Large Diameter Poles (3+ inches)

Large diameter poles command premium pricing but deliver exceptional structural performance for demanding commercial applications. These poles serve as primary structural elements in major construction projects, from load-bearing columns in restaurant construction to the main supports for large shade structures in water parks.

The thick walls of 3+ inch poles provide impressive strength-to-weight ratios that often surprise engineers accustomed to working with traditional materials. However, their size requires specialized handling equipment and stronger connection hardware, factors that must be considered during project planning and budgeting.

Diameter Specifications by Bamboo Type

Different bamboo varieties and synthetic products offer specific diameter ranges that determine their suitability for various applications.

Tre-Gai Bamboo Specifications

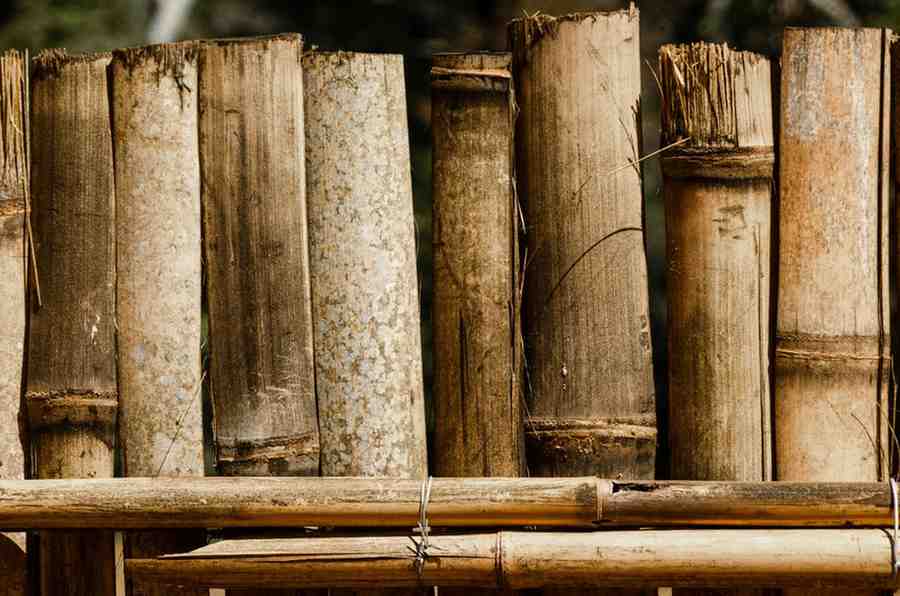

Tre-Gai bamboo delivers the largest natural diameter options, with poles averaging 2-3 inches and 3-4 inches in diameter. These construction-grade poles come in standard lengths of 8, 10, and 12 feet, making them ideal for structural applications requiring significant load capacity. The thick walls and pronounced nodes provide both strength and authentic rustic appearance, though natural variation means actual diameters can vary by 10-15% from stated specifications.

Solid Bamboo Specifications

Solid bamboo poles offer precision and reliability with consistent 1.5-inch average diameters and wall thickness ranging from 60-99% of the total diameter. Available in 8-foot and 10-foot lengths, these poles provide maximum strength per diameter inch due to their dense construction. The minimal splitting characteristics and consistent dimensions make them ideal for applications requiring precise fit-up and reliable connection details.

Synthetic Interlocking Systems

Artificial interlocking bamboo provides the most diameter options with precise 1-inch, 1.5-inch, 2-inch, and 3-inch sizes available in modular 18-20 inch sections. This system allows custom length creation while maintaining exact diameter specifications throughout the installation. The hollow construction accommodates wiring and utilities while fire-retardant properties meet commercial building codes.

However, keep in mind that synthetic bamboo poles are not structural.

HDPE Synthetic Options

High-density polyethylene synthetic poles offer the widest diameter range from 0.63 inches up to 2.88 inches, with lengths available from 116 to 112 inches. The precise manufacturing tolerances and UV-resistant construction provide long-term dimensional stability, while the hollow center design accommodates integrated lighting and utility systems that natural bamboo cannot support.

Load-Bearing Requirements by Application

Different commercial applications place vastly different structural demands on bamboo poles, and understanding these requirements before diameter selection prevents both over-spending on unnecessary capacity and dangerous under-sizing for critical applications.

- Decorative/Non-structural Applications: Ceiling treatments, wall coverings, and visual accents require minimal load capacity but benefit from consistent appearance and easy installation.

- Light Structural Needs: Fencing, privacy screens, and small pergolas demand enough strength to handle wind loads and occasional contact but don’t require engineered load calculations.

- Medium Structural Requirements: Restaurant facades, moderate-span roofing, and commercial screening need poles that can support distributed loads and meet basic building code requirements.

- Heavy Structural Demands: Load-bearing columns, large pergolas, and primary construction elements require engineering analysis and often building department approval.

- Safety-Critical Applications: Public spaces and high-traffic areas must meet specific building codes and safety factors, often requiring the largest available diameters regardless of cost.

Material Type and Diameter Considerations

The choice between natural and synthetic bamboo significantly affects diameter selection criteria, with each material type offering distinct advantages and limitations that impact project planning and long-term performance.

Natural Bamboo Diameter Variations

Natural bamboo poles exhibit inherent diameter variations that can range from 10-20% even within the same shipment. Some bamboo species have displayed remarkable strength under test conditions, with Bambusa tulda testing as high as 60,000 psi in tensile strength. These variations create both challenges and opportunities—the inconsistency can complicate precise engineering calculations, but the natural variation often enhances visual authenticity for projects where organic appearance matters more than dimensional precision.

Synthetic Bamboo Diameter Precision

Manufactured bamboo poles offer consistent dimensions that simplify engineering calculations and installation planning. Synthetic poles maintain their specified diameter within tight tolerances, making them ideal for projects requiring precise fit-up or standardized connection hardware. The predictable dimensions also mean that installation crews can pre-fabricate connections and hardware assemblies with confidence, reducing field labor and potential installation delays.

Hollow vs. Solid Construction Impact

The relationship between outer diameter and wall thickness dramatically affects actual load capacity, often more than the diameter measurement alone. The compressive strength of various bamboo species is predominantly between 40 and 80 N/mm², which is two to four times higher than most commercial wood species.

Cost Implications of Diameter Choices

Diameter selection creates cascading cost impacts throughout a project that extend far beyond the initial material purchase price, affecting everything from shipping logistics to long-term maintenance requirements.

Material cost scaling follows an exponential curve rather than linear progression, with 3-inch poles often costing three times as much as 2-inch options rather than just 50% more. Shipping and logistics considerations become critical for large diameter poles, which may require specialized transportation and can dramatically increase freight costs for distant projects. Installation complexity increases with diameter as larger poles require heavier equipment, stronger connection hardware, and more skilled labor for proper handling and assembly.

Common Diameter Selection Mistakes

Professional contractors and designers consistently see the same diameter selection errors across commercial bamboo projects:

- Over-sizing poles wastes project budget on unnecessary diameter without providing meaningful performance benefits

- Under-sizing for the application creates safety risks and potential structural failures

- Ignoring local building code requirements for pole sizing can result in failed inspections and expensive retrofits

- Failing to account for connection and joint requirements leads to awkward details and potential weak points

- Choosing diameter based solely on visual preference rather than functional requirements creates installations that may look appropriate but fail to perform adequately over time

Get Expert Diameter Selection Guidance for Your Project

Diameter selection represents just one of dozens of critical decisions that determine whether a commercial bamboo project succeeds or fails. While this guide provides the foundation for informed decision-making, every project brings unique challenges that benefit from professional consultation and hands-on material evaluation.

With over two decades of experience transforming creative visions into reality, amaZulu delivers the technical expertise and material quality that commercial projects demand. From theme park attractions to luxury resorts, our team helps architects and designers navigate diameter selection, material specifications, and installation challenges while ensuring projects meet both performance requirements and budget constraints.

Tristan Ishtar

VP of Sales

With over 11 years at amaZulu, Tristan brings deep expertise in tropical building materials and a customer-focused approach. He serves as a trusted consultant for architects and designers, providing expert guidance without high-pressure sales.