Tristan Ishtar

VP of Sales

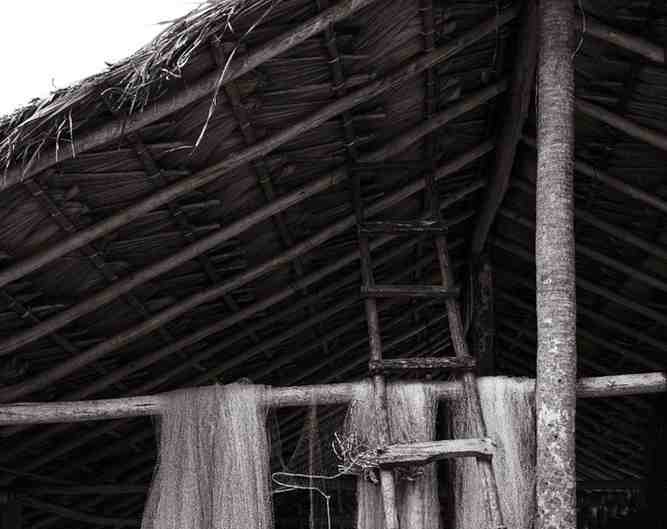

Picture two identical tiki bars built side-by-side on a Florida beachfront resort—same design, same aesthetic vision, different roofing specifications. Five years later, one maintains its vibrant tropical appeal while the other shows faded colors, brittle materials, and requires its third replacement cycle.

The only difference? The second one was made of modern synthetic roof tiles built to withstand coastal climates.

For theme park and resort designers working on oceanfront properties, salt air, UV exposure reflected off water surfaces, hurricane-force winds, and constant humidity create material stresses that inland specifications simply don’t address. Here’s what you need about how to approach thatch roofing on the coast.

UV Degradation Resistance: Testing Standards and Long-Term Performance

Ultraviolet radiation represents the single greatest threat to roofing material longevity in coastal environments, where reflected sunlight from water surfaces can nearly double UV exposure compared to inland installations.

The difference between adequate and exceptional UV resistance often determines whether a roofing system maintains its appearance and structural integrity for decades or begins showing signs of degradation within just a few years.

Industry-Standard UV Testing Protocols

Modern synthetic thatch roofing tiles undergo rigorous testing that far exceeds basic industry minimums. According to the American Society for Testing and Materials (ASTM), the most demanding products complete over 10,000 hours of accelerated sun exposure testing, simulating decades of real-world coastal conditions in controlled laboratory environments.

This testing protocol subjects materials to concentrated UV radiation equivalent to 15-20 years of continuous sun exposure while monitoring color stability, material flexibility, and structural integrity.

The testing process reveals critical performance differences between materials. Products that rely on surface coatings for UV protection typically show early signs of degradation, while tiles engineered with integrated UV stabilizers maintain consistent performance throughout the testing cycle.

Material Composition Impact on UV Resistance

The foundation of UV resistance lies in material composition rather than surface treatments. Virgin polymer formulations allow manufacturers to integrate UV stabilizers directly into the material matrix, creating protection that extends throughout the entire thickness of each tile. This approach contrasts sharply with recycled plastic alternatives, which often struggle with color consistency and UV stability due to contamination from previous applications.

High-density polyethylene formulations have emerged as the preferred base material for coastal applications, offering superior color retention and flexibility under UV stress. These materials maintain their structural properties even after years of intense sun exposure, while also providing the dimensional stability necessary for proper installation and long-term performance.

Installation and Maintenance Best Practices for Coastal Applications of Synthetic Thatch Roofing

Successful synthetic thatch roofing tile installation in coastal environments requires modified techniques that account for salt air corrosion, high humidity, and extreme weather exposure. Standard inland installation practices often prove inadequate for the unique challenges presented by marine environments, making specialized knowledge essential for long-term system performance.

Substrate Preparation and Fastening Systems

Coastal installations demand enhanced substrate preparation to prevent moisture infiltration and corrosion. Deck surfaces require additional sealing and vapor barriers to combat the constant humidity and salt exposure that can compromise structural integrity over time. Galvanized fasteners represent the minimum standard, with stainless steel or specialized coated fasteners providing superior long-term reliability in salt air environments.

Fastening patterns must also account for higher wind loads and thermal cycling common in coastal locations. Increased fastener density and specialized edge details help prevent uplift and water infiltration during storm events, while allowing for the greater thermal movement experienced in high-UV coastal environments.

Long-Term Maintenance Requirements

Coastal synthetic thatch roofing tile systems require proactive maintenance protocols that differ significantly from inland applications. Regular inspection schedules should focus on fastener integrity, as salt air can accelerate corrosion even in treated hardware. Panel condition monitoring becomes more critical due to the increased UV exposure and thermal cycling that can affect material performance over time.

Salt buildup removal represents a unique maintenance requirement for coastal installations. While synthetic materials resist salt damage better than natural alternatives, accumulated salt deposits can affect drainage patterns and create localized stress points.

Fire Safety and Building Code Compliance for Coastal Commercial Projects

Commercial coastal developments face unique fire safety requirements that extend well beyond standard residential building codes. Thatch for theme parks and resorts must meet stringent fire resistance standards while maintaining the aesthetic appeal that drives their business success.

Key Fire Rating Requirements:

- ASTM E-84 testing governs interior applications, measuring flame spread and smoke development in enclosed spaces

- ASTM E-108 standards apply to exterior installations, accounting for wind effects and outdoor fire behavior

- Class A fire ratings represent the highest performance level, required for most commercial coastal applications

- Commercial venue mandates typically require fire-retardant materials for any installation in theme parks, resorts, or restaurant environments

The difference between surface-applied and inherently fire-retardant materials becomes critical in coastal environments where salt air and moisture can degrade applied treatments over time. Materials with integrated fire retardants maintain their protective properties throughout their service life, providing consistent safety performance regardless of environmental exposure.

Wind Resistance and Structural Performance in High-Wind Coastal Environments

Hurricane-force winds present unique challenges for coastal roofing systems. Unlike inland installations, coastal projects must account for sustained high winds, sudden pressure changes, and wind-driven debris impact.

Miami-Dade County represents the gold standard for hurricane-resistant building codes, requiring specialized testing and certification that exceeds most national standards. Products approved for Miami-Dade applications typically exceed 110 MPH wind resistance ratings and undergo additional testing for impact resistance and cyclic loading.

Modern synthetic thatch roofing tiles incorporate flexible panel designs that allow controlled movement during high wind events. Rather than creating rigid resistance, these systems use engineered flex points that prevent catastrophic failure during storm conditions. This design philosophy recognizes that flexibility often provides better performance than rigid strength in extreme weather scenarios.

Panel attachment systems play a crucial role in wind resistance performance. Clipped panel designs allow controlled lifting and settling as wind pressures fluctuate, preventing the explosive failures common with rigid attachment methods. These systems essentially breathe with the storm, maintaining structural integrity while allowing pressure equalization.

The most advanced synthetic thatch roofing tile systems now achieve wind resistance ratings exceeding 110 MPH through careful engineering of both individual components and overall system design. These ratings reflect testing under conditions that closely mirror actual hurricane conditions, including wind-driven rain and debris impact scenarios.

Partner with Coastal Roofing Material Experts at amaZulu

Selecting the right synthetic roof tiles for coastal commercial projects requires more than grasping technical specifications—it demands working with suppliers who have proven experience in marine environments and can provide comprehensive project support from initial design through final installation.

amaZulu’s 22+ years of experience in tropical building materials includes extensive work on coastal commercial projects where weatherability and durability are non-negotiable. Our technical team can help you address the specific challenges of your coastal project, from selecting materials that meet local hurricane codes to ensuring proper fire safety compliance for commercial applications.

Tristan Ishtar

VP of Sales

With over 11 years at amaZulu, Tristan brings deep expertise in tropical building materials and a customer-focused approach. He serves as a trusted consultant for architects and designers, providing expert guidance without high-pressure sales.