Tristan Ishtar

VP of Sales

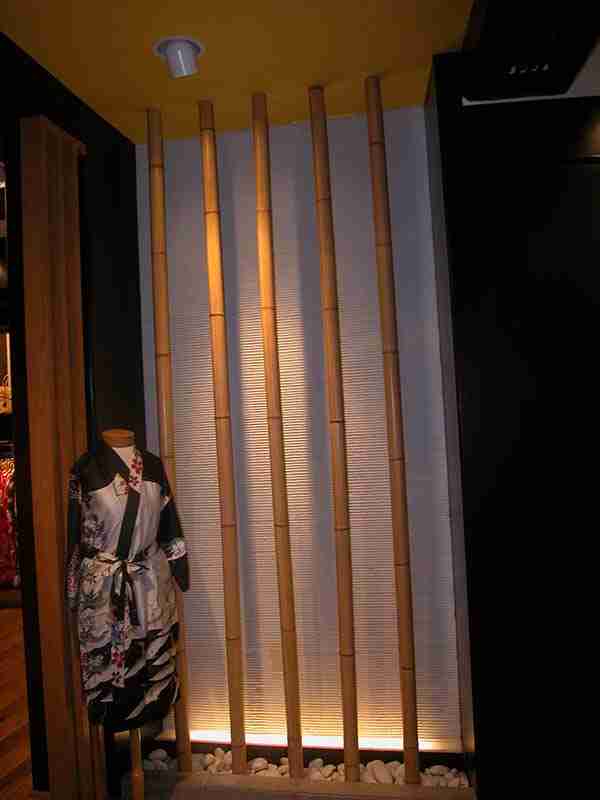

When the Las Vegas restaurant Lotus needed 1,200 bamboo poles for their architectural backdrop, they knew that procuring bamboo materials wasn’t like ordering office supplies and planned accordingly – but not everyone in the commercial world is as prepared.

The world of commercial bamboo sourcing operates on entirely different principles than residential purchases, with unique logistics challenges, volume thresholds that can make or break project budgets, and lead times that stretch across seasons and continents.

For project managers, architects, and procurement specialists working on theme parks, resorts, restaurants, and commercial developments, recognizing these industry-specific dynamics can mean the difference between a smoothly executed project and costly delays. Here’s what you need to know about the commercial bamboo supply chain.

Evaluating Volume Discounts for Commercial Bamboo Projects

The bamboo industry operates on vastly different volume expectations than most commercial buyers anticipate. While a homeowner might consider 20 poles a substantial order, meaningful commercial discounts don’t typically kick in until you reach the hundreds or thousands of pieces.

Key volume discount thresholds include:

- Baseline discounts – Most commercial suppliers offer 5% discounts as standard, but significant savings require much larger commitments

- Meaningful volume breaks – Expect to order several hundred to over 1,000 poles before accessing substantial pricing reductions

- Container-level pricing – The most significant discounts become available when orders justify direct container shipping from source countries

- Project-specific negotiations – Large installations like the Las Vegas restaurant’s 1,200-pole order can unlock custom pricing structures

The reality is that bamboo suppliers primarily serve commercial clients and price accordingly from the start. Unlike industries where volume discounts are heavily promoted, bamboo suppliers focus on competitive base pricing with incremental improvements for truly large-scale projects.

Essential Information for Accurate Commercial Quotes

Getting precise quotes for commercial bamboo projects requires providing suppliers with detailed project specifications upfront. The complexity of bamboo sourcing means that vague requests often result in inaccurate estimates that can derail budgets and timelines.

Critical information to provide includes:

- Project size and coverage area – Total square footage or linear footage needed, including backup quantities for potential waste

- Configuration complexity – Simple rectangular installations versus projects with angles, corners, or irregular shapes that increase material waste

- Application and location – Indoor versus outdoor use, climate conditions, and specific structural requirements

- Timeline requirements – Project start date, completion deadlines, and any milestone dates that affect delivery scheduling

- Plans and specifications – Architectural drawings, elevation views, and technical specifications when available

- Treatment requirements – Fire-retardant needs, custom finishes, or other specialty processing that affects lead times

Complex configurations can significantly impact material quantities due to cutting waste and unusable off-cuts. A chopped-up ceiling installation, for example, requires substantially more material than a simple rectangular application of the same square footage.

Lead Times and Production Schedules for Commercial Orders

Planning commercial bamboo projects requires comprehending production cycles that extend far beyond typical construction timelines. Natural processes involved in bamboo preparation create unavoidable delays that can impact project schedules significantly.

Standard Material Lead Times

Natural bamboo requires extensive preparation before it’s suitable for commercial use. The drying process alone takes four to six weeks under ideal conditions, and that’s after harvesting, straightening, and initial treatment. During Asia’s rainy season, these timelines can extend to five or six months as materials repeatedly get wet and must restart the drying cycle.

Specialty Treatment Timelines

Fire-retardant treatments add three to four months to standard lead times, making early specification crucial for projects with safety requirements. These treatments require specialized facilities and curing time that cannot be rushed. Alternative approaches like local spray application of Class A fire retardants can reduce lead times but require coordination with certified applicators.

Geographic and Seasonal Factors

Asian suppliers face monsoon seasons that can halt production for months at a time. Smart procurement teams plan around these seasonal patterns, placing orders well in advance of anticipated rainy seasons. European and South American suppliers face different seasonal challenges but generally offer more predictable timelines due to controlled storage facilities.

Logistics and Shipping Considerations for Large-Scale Projects

Container shipping transforms the economics of large bamboo orders. When quantities justify a full container, suppliers can arrange direct shipping from source countries to job sites, eliminating multiple handling steps and reducing costs significantly.

Freight costs vary dramatically based on order size and destination. Smaller orders typically ship via consolidated freight, adding time and handling costs. Large projects benefit from dedicated shipping arrangements that provide better control over delivery timing and material condition upon arrival.

Working with established commercial distributors offers advantages beyond pricing. These suppliers maintain relationships with reliable factories, conduct quality inspections, and recognize the documentation requirements for international shipments. They also stock materials domestically, reducing lead times for urgent project needs.

Storage and delivery coordination becomes critical for large installations. Bamboo materials require dry storage and careful handling to prevent damage. Successful projects involve detailed logistics planning that coordinates material delivery with construction schedules, ensuring materials arrive when needed without extended on-site storage requirements.

Get Expert Guidance for Your Commercial Bamboo Project

Successfully handling the complexities of commercial bamboo procurement requires partnering with suppliers who recognize both the materials and the unique demands of large-scale projects. With over 22 years of experience sourcing directly from villages and factories worldwide, amaZulu has built the relationships and expertise necessary to guide projects from initial concept through final installation.

Whether you’re planning a major resort development or need to assess lead times for specialty treatments, amaZulu’s team can quickly estimate project scope and provide the detailed logistics planning that ensures materials arrive on schedule and within budget.

Contact amaZulu today at (877) 243-5309 to discuss your project requirements and discover how their global sourcing network can transform your vision into reality while avoiding the costly delays that derail unprepared projects.

Tristan Ishtar

VP of Sales

With over 11 years at amaZulu, Tristan brings deep expertise in tropical building materials and a customer-focused approach. He serves as a trusted consultant for architects and designers, providing expert guidance without high-pressure sales.