Tristan Ishtar

VP of Sales

Every year, millions of visitors escape to tropical-themed resorts, theme parks, and restaurants where thatched roofs transport them to distant shores. But there’s a critical decision that happens before that: whether to go with natural or synthetic thatch.

In this guide, we’ll compare synthetic to natural thatch when it comes to commercial projects, and how to make the right decision for your next design.

Commercial Durability Requirements for Thatch Roofing: The 15-20 Year Standard

Commercial properties operate under fundamentally different constraints than residential projects. When you’re designing for thousands of daily visitors, weather exposure, and strict safety regulations, material longevity isn’t just preferred—it’s essential for business viability.

Theme Parks and Entertainment Venues

Theme parks face the ultimate durability test. Attractions must withstand constant guest interaction, severe weather events, and intensive maintenance schedules while maintaining their visual appeal. A thatched roof that shows wear after two years doesn’t just look unprofessional—it undermines the entire themed experience that guests pay premium prices to enjoy.

Resorts and Hospitality Properties

Resort properties balance aesthetic authenticity with operational efficiency. Guests expect pristine tropical ambiance throughout their stay, but behind the scenes, property managers need materials that won’t require disruptive maintenance during peak seasons. A thatched pool cabana that needs repair work during spring break season represents lost revenue and negative guest experiences.

Zoos and Educational Facilities

Zoos present unique challenges where animal safety intersects with public education. Thatched structures in animal habitats must withstand both weather exposure and potential animal interaction while maintaining educational authenticity. Moreover, many facilities require materials that won’t introduce harmful chemicals or create pest attraction near animal enclosures.

Decision Matrix: When to Choose Synthetic vs Natural Thatch

Making the right material choice requires matching your project’s specific conditions with each material’s strengths. Rather than defaulting to cost comparisons, successful commercial projects evaluate climate, operational demands, and long-term facility goals to determine the optimal thatch solution.

Climate-Based Decision Guidelines

Choose Synthetic Thatch in humid subtropical climates (Florida, Gulf Coast, Hawaii) where natural materials face constant moisture challenges and 3-5 year replacement cycles. Synthetic materials maintain consistent performance regardless of humidity levels, eliminating climate-related maintenance variability.

Consider Natural Thatch in arid climates (Arizona, Nevada, parts of Texas) where low humidity allows 15-20 year lifespans that rival synthetic alternatives. Desert conditions minimize the organic decay issues that plague natural materials in humid environments.

Project Type Recommendations

Theme Parks and High-Traffic Entertainment should prioritize synthetic materials due to minimal maintenance windows and constant visitor exposure. The ability to clean and maintain synthetic thatch quickly between operating seasons provides operational advantages that justify higher initial costs.

Luxury Resorts and Boutique Properties may benefit from natural thatch in protected applications where authentic aesthetics matter more than maintenance convenience. Consider natural materials for accent features and synthetic for primary weather-exposed structures.

Synthetic Thatch: Engineered for Commercial Longevity

Modern synthetic thatch represents a complete reimagining of traditional roofing materials using advanced polymer technology. These engineered solutions address every major failure point of natural materials while maintaining the visual characteristics that make thatch appealing for commercial applications.

Key Performance Features:

- 15-20+ year manufacturer warranties with specific performance guarantees covering UV resistance, color stability, and structural integrity

- Hurricane-force wind resistance with documented testing up to 110 MPH

- Class A fire ratings meeting ASTM E84 and ASTM E108 commercial building codes without additional chemical treatments

- UV stabilization technology preventing the color fade and material degradation that plague natural alternatives

- Minimal maintenance requirements reducing long-term operational costs

- Consistent appearance retention maintaining the same aesthetic quality for decades

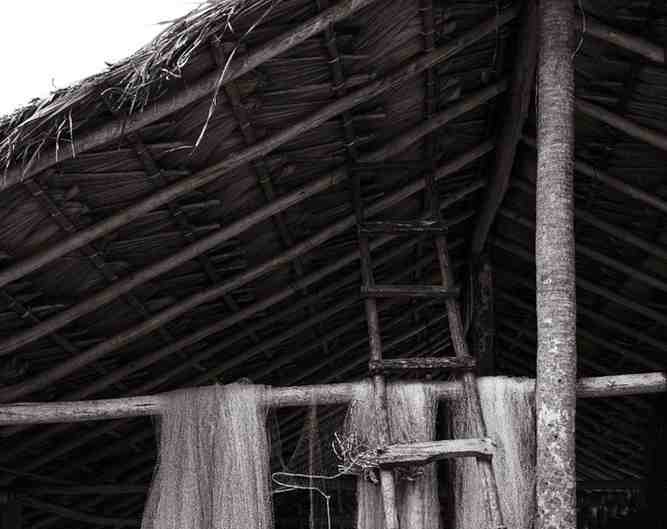

Natural Thatch: Traditional Authenticity with Maintenance Realities

Natural thatch delivers unmatched visual authenticity; the subtle color variations, organic texture, and cultural significance make it irreplaceable for certain high-end applications where authenticity matters more than maintenance convenience.

However, the maintenance reality varies dramatically by climate. In humid environments like Florida, natural thatch typically requires replacement every three to five years due to moisture damage, pest infestation, and organic decay. Palm thatch roofs require rethatching every 5-7 years, while other materials like reed may last up to 15 years before requiring replacement.

Conversely, in arid climates like Arizona or parts of Texas, natural thatch can last 15 to 20 years due to the lack of moisture-related degradation. This dramatic performance difference means location plays a crucial role in material selection decisions for commercial projects.

Fire Safety and Building Code Compliance

Fire safety represents the most critical consideration for commercial thatch installations, with stringent building codes requiring specific performance standards that many natural materials cannot meet without treatment.

ASTM Testing Standards and Requirements

Commercial buildings must comply with ASTM E84 for interior applications and ASTM E108 for exterior applications. These standards establish minimum thresholds for flame spread and smoke development that all roofing materials must achieve.

Synthetic Fire Resistance Capabilities

Quality synthetic thatch products incorporate fire-retardant properties during manufacturing, achieving Class A ratings without additional chemical treatments. This built-in fire resistance maintains its effectiveness throughout the material’s lifespan, unlike surface treatments that may degrade over time.

Natural Thatch Fire Treatment Options

Natural thatch can achieve Class A fire ratings through chemical treatment processes, but these treatments require careful application and ongoing maintenance to remain effective. The treatment adds cost to initial installation and may require periodic reapplication depending on weather exposure.

Maintenance Requirements: Synthetic vs Natural

The maintenance philosophy differs completely between synthetic and natural thatch, with implications for both operational budgets and facility management procedures.

Synthetic Thatch Maintenance:

- Occasional cleaning for aesthetic maintenance using standard cleaning procedures

- Basic structural inspections integrated with routine building maintenance schedules

- No pest control treatments or organic decay prevention required

- Minimal weather-related repair needs due to engineered material stability

Natural Thatch Maintenance:

- Regular pest inspections and prevention treatments to control insects and rodents

- Moisture management systems including ventilation and drainage maintenance

- Periodic section replacement due to organic degradation and weather damage

- Seasonal preparation for storm seasons including loose material securing

- Skilled craftsperson requirements for authentic repairs and maintenance procedures

- Mold and mildew prevention treatments in humid climates

Total Cost of Ownership Analysis

Smart commercial property investment requires looking beyond initial material costs to understand true long-term expenses. The apparent cost advantage of natural thatch often disappears when maintenance and replacement cycles are properly calculated.

Initial Investment Comparison

Synthetic thatch materials typically cost three to eight times more than natural alternatives at initial purchase. This significant upfront cost difference means designers and architects must carefully examine their options during the planning phase.

Long-Term Operational Costs

Natural thatch’s lower initial cost becomes expensive over time through maintenance labor, material replacement, and operational disruption. A thatched roof requiring replacement every four years generates five replacement cycles over a 20-year period, each involving material costs, skilled labor, and business disruption during installation.

Synthetic alternatives eliminate most replacement cycles while reducing maintenance labor to basic cleaning procedures. The labor savings alone often justify the higher initial investment, particularly for properties in remote locations where skilled craftspeople are expensive to source.

Application Suitability by Commercial Project Type

Different commercial applications create varying performance demands that influence optimal material selection.

Theme park attractions demand maximum durability due to high visitor traffic and minimal maintenance windows. Synthetic materials excel in these applications where consistent appearance and minimal disruption matter most.

Resort pool areas present unique challenges with chemical exposure from pool maintenance and constant moisture from splash zones. Synthetic thatch handles chlorine exposure and frequent water contact without degradation, while natural materials may suffer accelerated decay in these environments.

Restaurant outdoor dining areas require materials that maintain an attractive appearance despite food service operations and frequent cleaning requirements. Synthetic thatch can be cleaned by knocking any debris off with a broom – it slides right off.

Zoo exhibits balance authentic appearance with animal safety requirements. Many facilities prefer materials that won’t attract pests or create organic debris in animal habitats.

Bring Your Project to Life with amaZulu

Choosing between synthetic and natural thatch is only the first step—partnering with the right supplier ensures your vision lasts for decades. For over 22 years, amaZulu has helped theme parks, resorts, zoos, and restaurants worldwide create stunning, code-compliant tropical environments with both natural and synthetic thatch solutions.

Call us today at or request a quote online, and let’s make your dream a reality.

Tristan Ishtar

VP of Sales

With over 11 years at amaZulu, Tristan brings deep expertise in tropical building materials and a customer-focused approach. He serves as a trusted consultant for architects and designers, providing expert guidance without high-pressure sales.